Des-Case is a leading name in the breather industry. In fact, the company was the first to produce a desiccant breather, which is still widely used in the wind industry today. For decades, Des-Case has partnered with leading global manufacturing companies to produce and deliver quality products. Kurz Wind has all the details you need on breathers and their benefits for wind applications.

What do breathers do?

A breather is used to protect equipment from contamination. The breather is designed to replace certain parts on your wind equipment, including the original manufacturer breather cap and the original dust cap. By replacing these parts, breathers can filter out even the smallest particles that the caps won’t always catch. In turn, they allow the equipment to operate more efficiently, and they can reduce the amount of downtime and repairs that equipment operators may otherwise face. Breathers work in a precise manner to control contamination. Whenever air enters the breather, the desiccant filter removes harmful particulate matter. This eliminates moisture that can otherwise accumulate in the system. The silica gel will draw excess moisture from the equipment reservoir, which helps to keep the equipment dry during shut-down or when it needs to be serviced.

Why do breathers matter in wind?

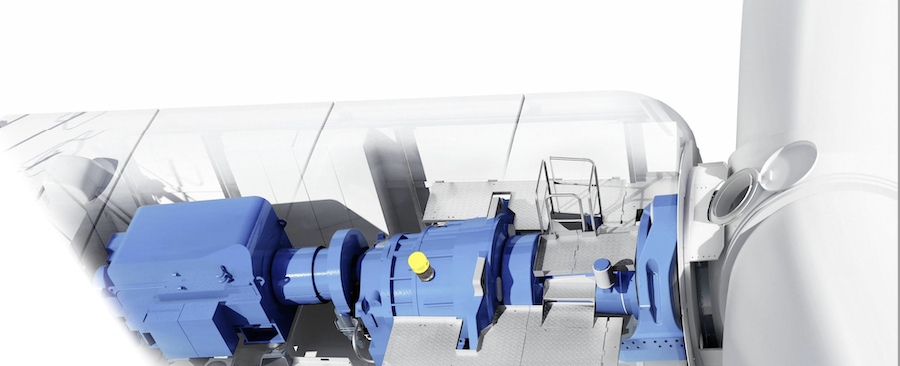

Breathers are critical in wind equipment. They are generally placed in wind turbine gearboxes, and they are often required to operate in demanding conditions. For instance, the oil in a wind turbine gearbox can change viscosity frequently and dramatically due to fluctuating temperatures. Humidity and condensation are other environmental elements that can influence oil’s viscosity. Breathers are an important tool to help manage contamination despite the rapid changes in the gearbox oil, as they are considered to be the front line of defense against airborne contaminants. They also allow air to enter the gearbox as it cools, which keeps contaminants and water vapor from entering the wind turbine’s fluid system. Breathers often work in tandem with filters, which remove fine particulate matter from the gearbox oil. Along with having a breather in their gearbox, wind turbine operators should always make sure that there is enough oil in their gearbox.

How do turbine owners monitor the health of Des-Case products?

For convenience, Des-Case products can be monitored remotely. Remote monitoring provides comprehensive monitoring coverage to ensure optimal machine performance.

Wind turbine operators can monitor the health of Des-Case products using a wired breather. The wired breather monitors breather condition in real time. The monitor works remotely for convenience, and it can eliminate more expensive up-tower service work. From the remote monitoring report, the turbine operator can view the status of all breathers and access trend data from the web at any time and at any location.

Information collected through remote monitoring is then sent to a phone app to provide real-time updates on system performance. Diagnostic monitoring is also an option, which can let operators know right away if there is a problem with their system that needs to be fixed.

To find out more about breathers and their advantages for wind energy equipment, don’t hesitate to contact the Kurz Wind professionals today.

Categorised in: Latest Wind Power Industry News - Kurz Wind Division

This post was written by Matt Passannante

Comments are closed here.